Laser modules are the building blocks of laser systems. It takes many kinds of lasers to make up a complete system. Laser modules can be categorized based on different criteria like their gain medium, wavelength, power levels, collimating optics, and other features.

Laser systems are made up of different modules to achieve the desired laser performance. They include beam expanders, beam delivery optics like lenses and mirrors, power supplies to supply power to the modules, and other components. When it comes to laser modules, there are different types.

Types of laser modules

1) Solid-state lasers (SSL)

These lasers use a synthetic sapphire crystal as an optical resonator, called an “optical table”. The most common type uses a rod of material such as Nd:YAG or fiber doped with rare-earth elements. Fiber solid-state lasers are used in the field of scientific research. They are also used for industrial purposes.

These lasers are optically pumped, with the energy coming from a flash lamp or diode laser. This is usually done using a built-in mirror, called a “lasing crystal”, which captures most of the light energy and reflects it back to be passed through another crystal with less reflectivity (total internal reflection).

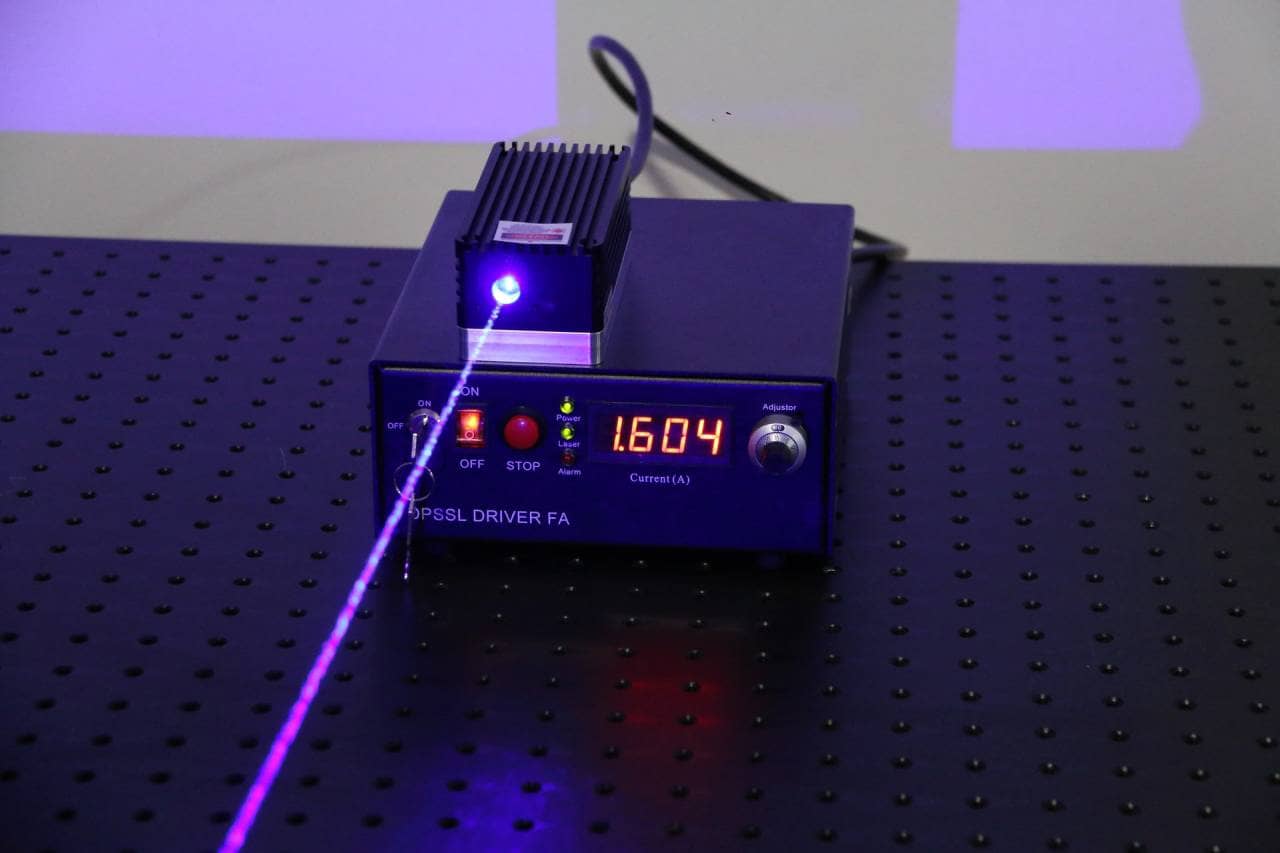

2) Diode-pumped solid-state (DPSS) lasers

These are available in DPSS- type modules. DPSS lasers are solid-state lasers that emit coherent light through the interaction of electronic energy and active, or excited, atoms in a semiconductor material known as DPSS. DPSS stands for Diode Pumped Solid State, which means it has no gas tube, much like CO2 lasers. These lasers typically use an infrared laser diode that pumps a crystal containing neodymium, DPSS, and yttrium aluminum garnet (YAG). This causes the DPSS to produce light at a variety of wavelengths.

DPSS lasers are also very small compared to other types of lasers. DPSS modules allow for the most flexible laser characteristics, such as fluctuations in wavelength and pulse duration. This type of lasers emits coherent light through the interaction of electronic energy and active, or excited, atoms in a semiconductor material known as DPSS. DPSS modules allow for the most flexible laser characteristics, such as fluctuations in wavelength and pulse duration. DPSS stands for Diode Pumped Solid State, which means it has no gas tube, much like CO2 lasers. DPSS lasers produce different light wavelengths and the constant wavelength is very important for many industries and manufacturing purposes. They can be used in telecommunications, medical equipment, and mining applications.

3. External cavity lasers (ECL)

The first group of ECL types is the edge-emitting lasers, which emit beams from the facet. The easiest way to distinguish them is by looking at their lens mounts: if they have a single or double focus mount, then they are edge-emitting lasers. In edge-emitting lasers, the current is injected into a waveguide that runs down one side of the semiconductor crystal. As the carriers travel from the injection point to the other end of the crystal they are reflected by a mirror formed in a ridge on top of an ohmic contact. The total internal reflection at this interface results in the emission of most of the carriers from the top surface. The emitted wave then, by total reflection, reaches a second mirror formed in another surface that limits emission to an edge.

The lasers are fabricated with photolithography techniques similar to those used for integrated circuits, with process steps including doping and implantation, epitaxial growth, optical and electrical contacting, metallization, and planarization. All of these can be done with thin-film deposition techniques.

4. Quantum cascade laser (QCL)

Laser modules use laser beams to do a multitude of tasks from projection screens to communication. The lasers are known for being powerful and efficient. There are three common types of QCLs: mid-infrared, far-infrared, and terahertz lasers. The type that a person chooses depends on the application.

Mid-infrared lasers are effective for material processing and collecting spectroscopy data. Far infrared lasers emit low power but pulsed beams that are used in spectroscopy which is analyzing chemical components of objects. Terahertz lasers emit beams at frequencies that fall between microwaves and infrared waves which makes them highly accurate in terms of performing spectroscopy and imaging.

5. Free electron laser (FEL)

This is a type of laser system which uses electrons, instead of atoms or molecules to produce light using stimulated emission. It is used for materials welding, lithography, and power measurements.

There are six types of FELs being used, namely: undulator-based free-electron lasers (FEL), undulator/wiggler-based FELs, high harmonic generation (HHG) based FELs, Raman FELs, disk-based FELs, and laser plasma-based free-electron lasers.

Undulator based free-electron lasers (FEL)

This system is composed of undulators which are essentially electron storage rings that generate coherent radiation. Before the electrons are sent to the ring, they are first accelerated by an electrostatic field located near a linear accelerator. The FEL uses this stored energy to create electromagnetic waves at microwave frequencies(0.1 to 30 GHz)

The system is being used in the field of atomic and molecular physics, nonlinear science, and quantum optics.

Undulator/wiggler based FELs

This type consists of a wiggler which creates a stable magnetic field. This field causes the confined electron beam to go back and forth changing its direction. This beam is then hit by a second electron beam to produce light.

The technology allows the laser beams to be used in materials science, material fabrication, biology, and medicine.

High harmonic generation (HHG) based FELs

This system uses high-intensity lasers which are focused on particular atoms or molecules. It is similar to the undulator FELs, but they use different electron energies. These lasers are uniquely used in thin-film processing, thin material fabrication, and semiconductor process applications.

High harmonic generation (HHG) based FELs make the most out of high-power lasers to produce short pulses of light at ultraviolet (UV) wavelengths. This technology is applied in the fields of plasma physics, chemistry, semiconductor research, and materials fabrication.

Raman FELs

This laser type is made up of a chain of optical parametric amplifiers which are used to increase the power of laser beams. It is also known as chirped pulse amplification (CPA) technology.

The Raman FELs are used for gas and material analysis as well as the generation of high-power UV pulses.

Disk-based FELs

The system uses disks with an active gain medium which is placed between two mirrors to amplify the light efficiently. The disks are typically made of solid-state crystals like Yb:glass or Er:YAG lasers, which are on a growth substrate.

It is being used in the material processing, micro-welding, and marking of metals. The FEL is also used for extreme-ultraviolet lithography.

Laser plasma-based free-electron lasers (FELs)

This system uses a laser to create a high density of electrons and a second laser beam that hits them to produce light.

The technology is used in the fields of attosecond physics, plasma surface interactions, and chemistry. Other applications are biological imaging, material processing, micro-welding, and coating for glasses.